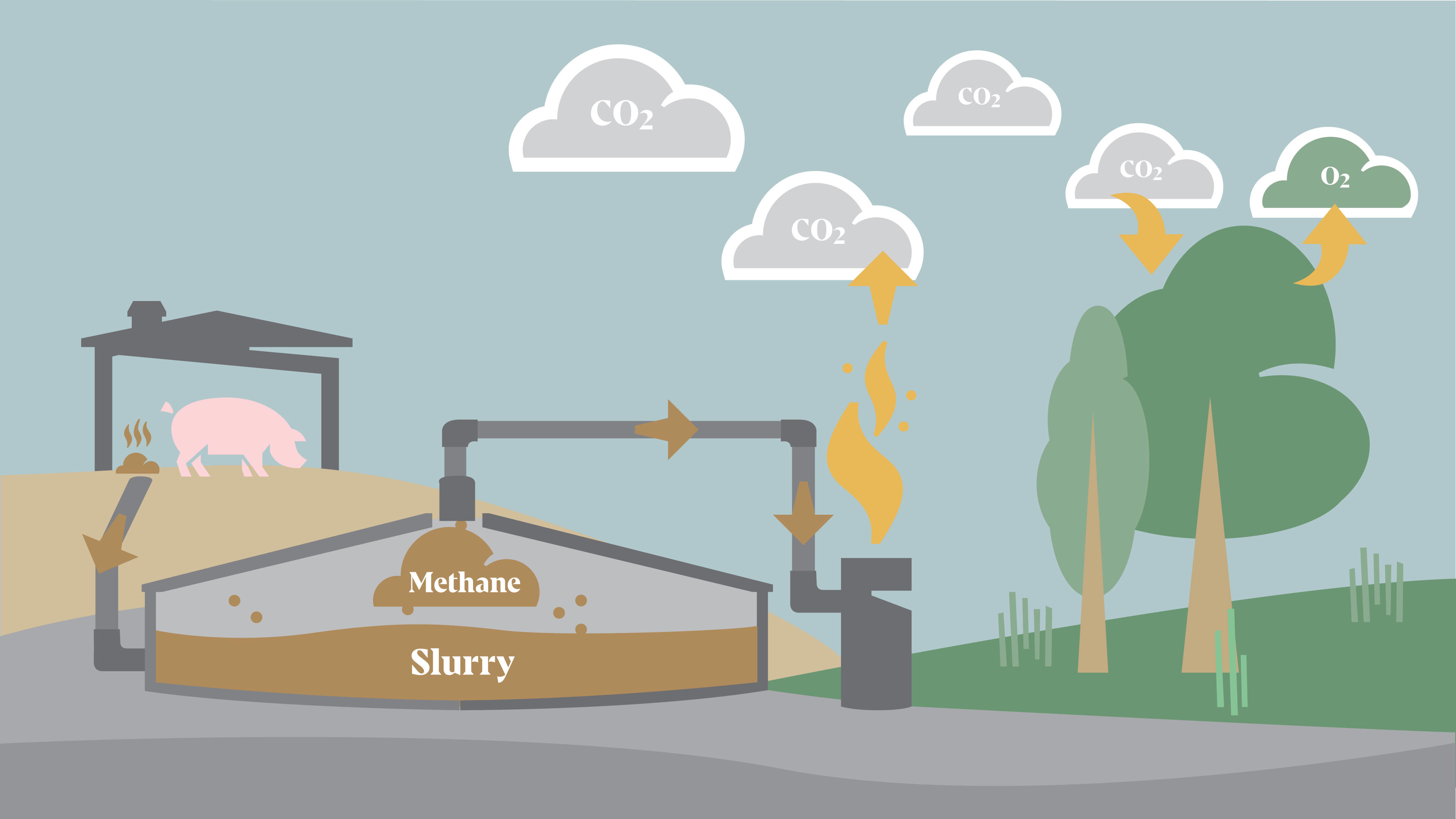

It may sound strange that a burning gas flare at a slurry tank can reduce the climate footprint of a kilogram of pork. But it is an undisputed fact because when it is methane gas from a manure tank driving the flame, the harmful greenhouse gas is converted into CO2. The method is relatively new, and calculations show that the climate impact from the methane burned off is reduced by over 95 percent.

- From the start, we have seen enormous potential in this technology, which is why we have chosen to invest in AgroGas. In this way, we ensure that Danish Crown's owners, the Danish farmers, can be at the forefront of the technology, and as a company, we can contribute to the development of one of the new technologies that can truly contribute to a green transformation of agriculture, says Jais Valeur, Group CEO of Danish Crown.

The technology originates from the company Deponigas ApS, which has been working on gas extraction from landfills in Denmark for over 20 years. In 2019, the first attempt to use the technology to burn off methane gas from slurry began, and when the initial trials showed enormous potential, the company AgroGas was founded with the aim of spreading the technology within agriculture. This initially led to a partnership with Danish Crown, which is now expanding to co-ownership.

- We have been pleased with the partnership with Danish Crown. Therefore, we see great potential in the co-ownership, which will accelerate the rollout of AgroGas plants and, most importantly, the scaling of the business primarily in Denmark and then abroad for the benefit of the climate, say Peter Foged Larsen and Mikkel Kastensand, founders of AgroGas.

The AgroGas technology is currently part of the GUDP project LESS (Low Emission Slurry Storages), which aims to validate the effect with the goal of being listed among the most promising future technologies for reducing methane emissions from manure tanks. The project is conducted in collaboration with SEGES, Landia, and Aarhus University, where senior researcher Anders Peter Adamsen describes the technology as promising.

- It appears that with effective sealing of the covered slurry tanks and active gas collection from the slurry tanks, methane gas can be collected and burned off almost year-round, says senior researcher Anders Peter Adamsen, who, together with colleagues and AgroGas, has been working on optimizing and documenting the technology for the past few years:

- This is an extremely important step, as methane gas is an incredibly potent greenhouse gas, and one that we can address with this new technology. We have a great need to find technologies that can reduce methane gas from slurry tanks, as, for example, frequent discharge of slurry in stables will result in more methane gas in the slurry tank.

In Danish Crown, attention is drawn to the fact that the project is a good example of how Denmark can develop technologies that can reduce greenhouse gas emissions from agriculture.

- As a company, we have a stated goal of driving development in the pursuit of creating a more sustainable future for meat. This is a very concrete initiative, and we will work diligently to both develop and expand the technology, and I certainly would not rule out that other types of projects could arise in the future, says Jais Valeur.

Currently, it is being investigated whether the reduction in the CO2 footprint resulting from burning off methane gas from slurry tanks can be converted into CO2 certificates. It is expected to be clarified within a few months.

The first plant is currently being commissioned, and more are on the way. Results are continuously evaluated, and if they meet expectations, the plan is to offer the technology to all cooperative owners in Danish Crown.

Why does flare technology make a difference for the climate?

It does because methane gas harms the atmosphere 28 times more than CO2...

...BUT when one of our farmers ignites the flare and the flame burns, methane gas is converted into CO2. In fact, when a kilogram of carbon in methane gas is burned, it is converted into precisely one kilogram of CO2 measured as carbon. Therefore, the CO2 emissions from each kilogram of burned gas is reduced 28 times.

Technically, the flare system works like this:

A pump draws methane gas from the top of a closed slurry tank. From there, the methane gas is pumped to the flare, where it is burned off and converted into CO2. It is better to emit CO2 than methane because methane gas traps much more of the heat radiating in the atmosphere from the earth and thus contributes more to global warming. Additionally, plants and trees naturally absorb CO2 as part of their growth for biomass formation.