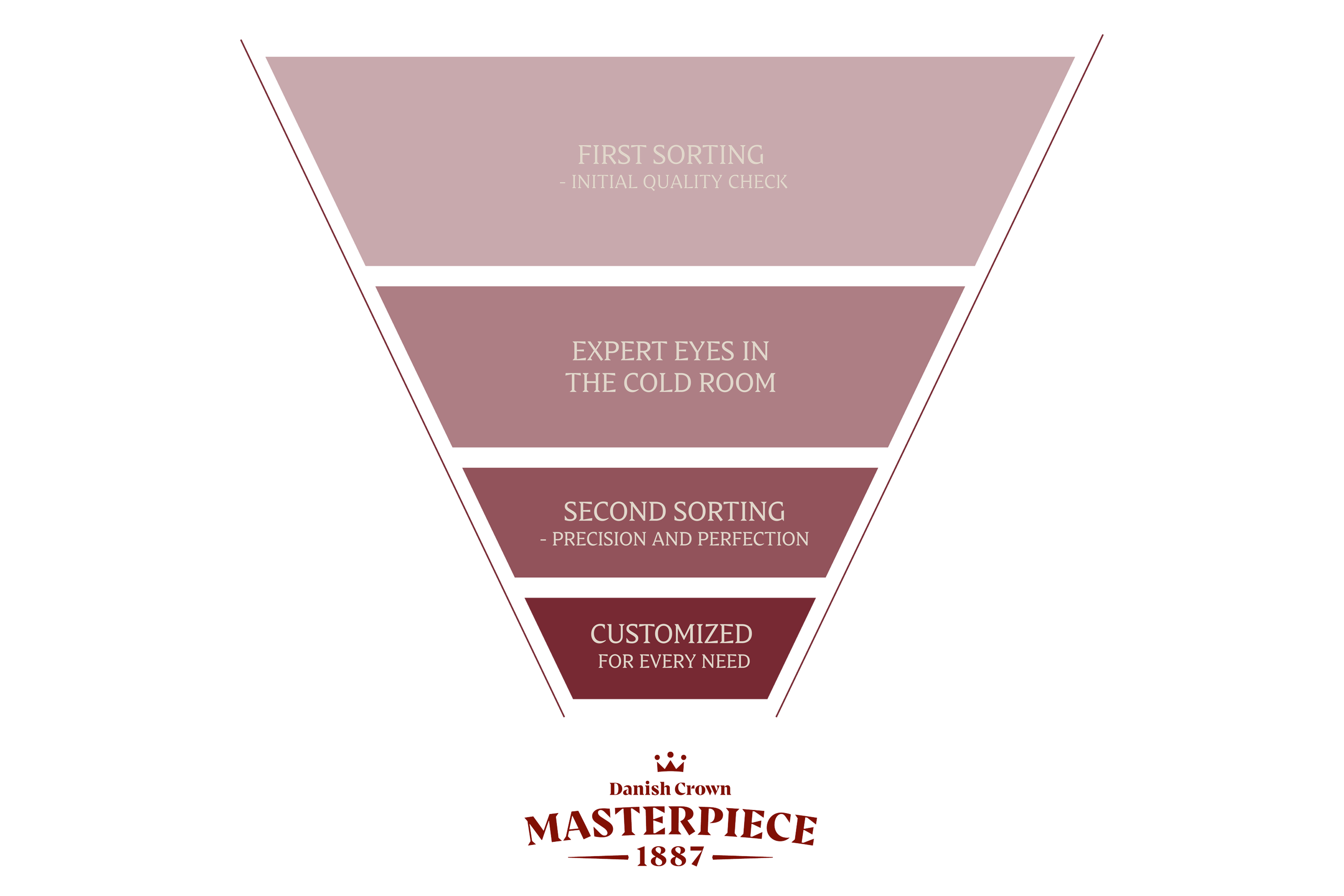

FIRST SORTING - INITIAL QUALITY CHECK

In the first sorting, cattle are scanned by either eyes or our BBC3 system to reveal a detailed three-dimensional image of the bodies. They are then classified according to criteria including shape, fatness, weight and colour. On this basis, meat is graded and grouped for the cold room. Here, experts check for evidence of perfect slaughtering. The first ‘marbling check’ is also performed by examining the scan based on defined criteria including the shape of the inner thigh and neck.

EXPERT EYES IN THE COLD ROOM

Our process, overseen by Master Selector Tobias Nybroe, ensures that each selection is made with precision and expertise. Tobias leads a team of skilled selectors, who act as Tobias' "eyes" in the cold room, meticulously picking and selecting each piece of meat. Each selector is trained extensively to understand the unique mindset, requirements, and expectations of every customer, a skill learned through extensive training and experience.

SECOND SORTING - PRECISION AND PERFECTION

Second sorting takes place during the cutting process. The real selection starts when the carcasses have been divided into pistol and wing, and only now can our selectors truly judge the marbling. Our skilled selectors use their trained eyes to visually assess the marbling and quality, allocating the best cuts to meet individual customer criteria.

CUSTOMIZED FOR EVERY NEED

Our premium selection is not off-the-shelf. Every week, our customers receive carefully selected premium meats tailored to their specific needs. We ensure that each selection is made with precision and expertise, delivering exceptional quality every time. Of the goods included in MASTERPIECE 1887, every single item is the result of an expert’s visual selection. This process is manual and irreplaceable by machines, ensuring that each premium cut is perfect.