Our ambition

We leverage between talking about food loss and food waste in the production and at home at the consumer. The efforts and actions differ, which is why our ambitions differ too. Explore them alongside concrete actions below.

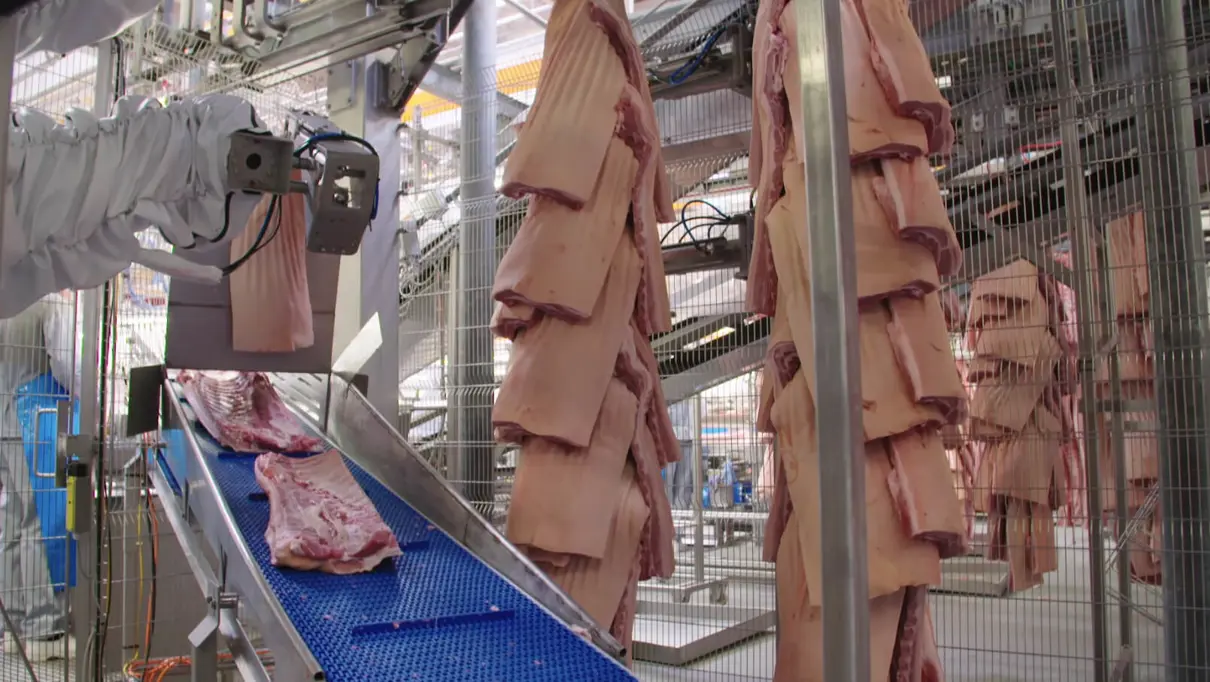

- Food loss and food waste at production level: We aim to put every part of the animal and our other raw materials to good use at our production facilities.

- Food waste at consumer level: We aim to reduce food waste in collaboration with customers and consumer organisations. Read more on how we’re combatting food waste here.

How do we utilise the animal?

We take good care of our raw materials and through innovation and market development try to utilise as much as possible for edible products. For example, our production facility in Haarlem, the Netherlands sells uneven bacon slices to Swedish and Danish food service customers at a reduced price.

If it is practically and economically viable to sell our by-products for human consumption, we ensure our production process is organised in such a way that parts of the animals are separated from the inedible parts and treated in a way that maintains product quality and food safety.

Traceable hides turned to fashionable bags

Besides food, pharmaceutical ingredients like heparin and insulin, our hides are also transformed by our subsidiary Scan-Hide and their separate brand, SPOOR, who provides fully traceable leather for fashion and furniture brands. They have used new technology and innovation to create a tanning method making the leather fully biodegradable and compostable at end life.

The latest collab includes partnering with British designer who turns the traceable hides into unique designer bags.

Making the most of the inedible parts

The inedible parts of the animal also have value, and we ensure they form part of a circular biosystem in which they are used for a number of other purposes when possible. Our processes for by-products have been built on the waste hierarchy and the bio-based value pyramid, e.g., our production processes and sorting practices are structured so as not to downgrade any by-products by for example mixing products that could be used for feed with products not suitable for this purpose. If feed is not economically and practically viable, then we sell our by-products to be used in green energy production e.g., as part of our partnership with the biogas company Bigadan. Read more about the partnership here.